Launch of AMP with TTM technologist

01Start-up

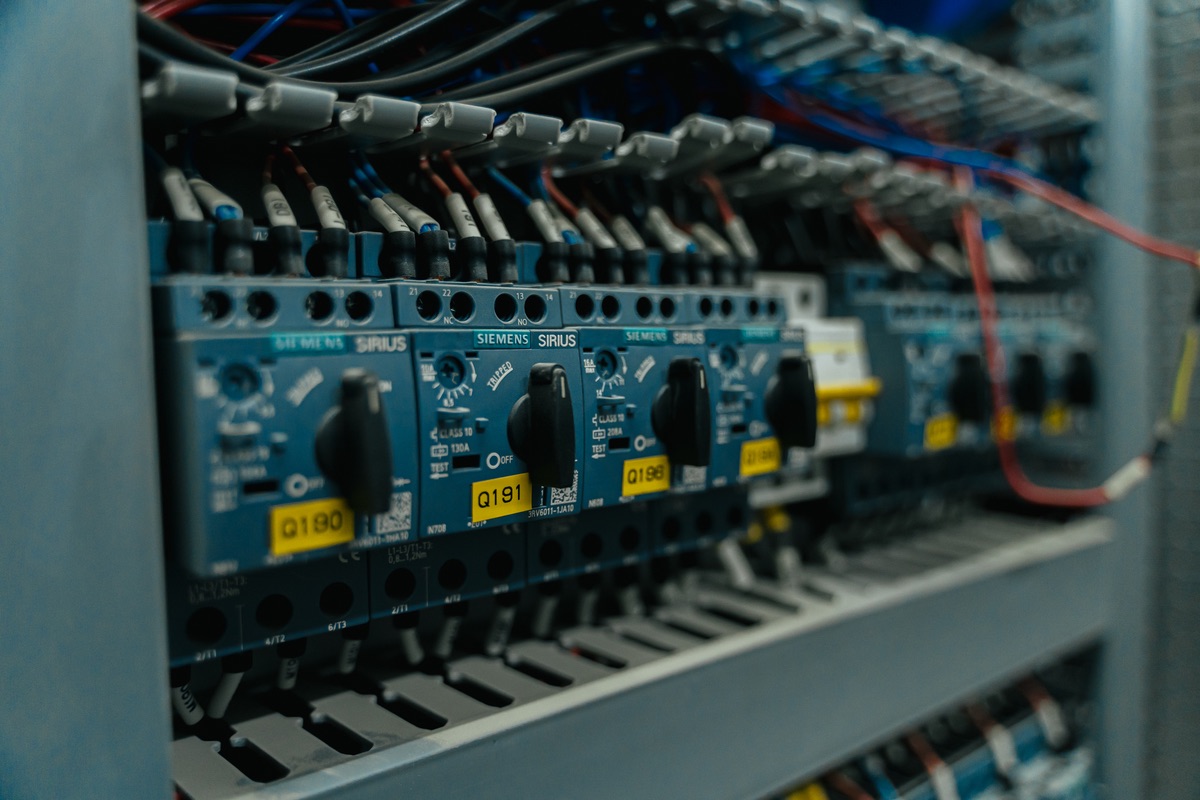

During the commissioning works cyclograms are formed and asphalt meshing units and assemblies are set up for actual materials and recipes of road construction organization of the Customer.

Acceptance of equipment into operation is carried out with a set of such measures as the quality control of the sieve, the homogeneity of the mixture, etc. After the joint release of the tonnage of the mixture agreed with the Customer according to the given recipe, the act of commissioning the equipment is signed.

TTM Company offers as an additional option a new unique service for the AMP market: factory pre-commissioning.

Debugging is carried out by TTM technologist, who knows not only the specifics of the plants, but also deeply understands the whole process and the interaction between its different parts.

This kind of initial factory debugging gives the Client the opportunity to use it in the future with 100% efficiency.