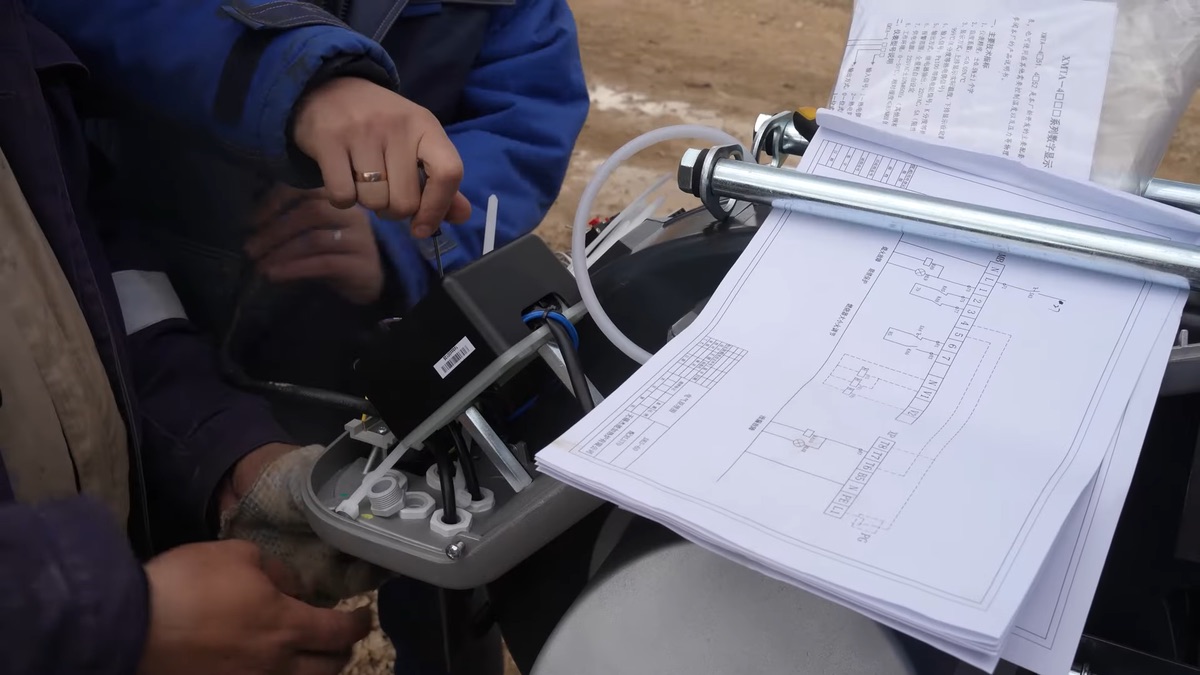

Assembly and start-up of equipment

01AMP assembly services

Installation of an asphalt mixing plant is a complex and responsible process of plant assembly and equipment adjustment, which requires highly qualified specialists. TTM provides its customers with the services of a head installation: installation and commissioning works are carried out under the guidance and with the participation of experienced installers TTM.

The plants are supplied to the customer by separate units in containers that meet the requirements of sea or rail transport. Small parts are packed in wooden boxes. This guarantees their safety, and therefore the quality of the entire asphalt mixing plant. At the installation site they are gathered in a single complex.

Thanks to the use of robots in the factory, it is possible to achieve high accuracy in the manufacture of units, which makes the installation fast and the fitting of various units and connections of equipment reliable.